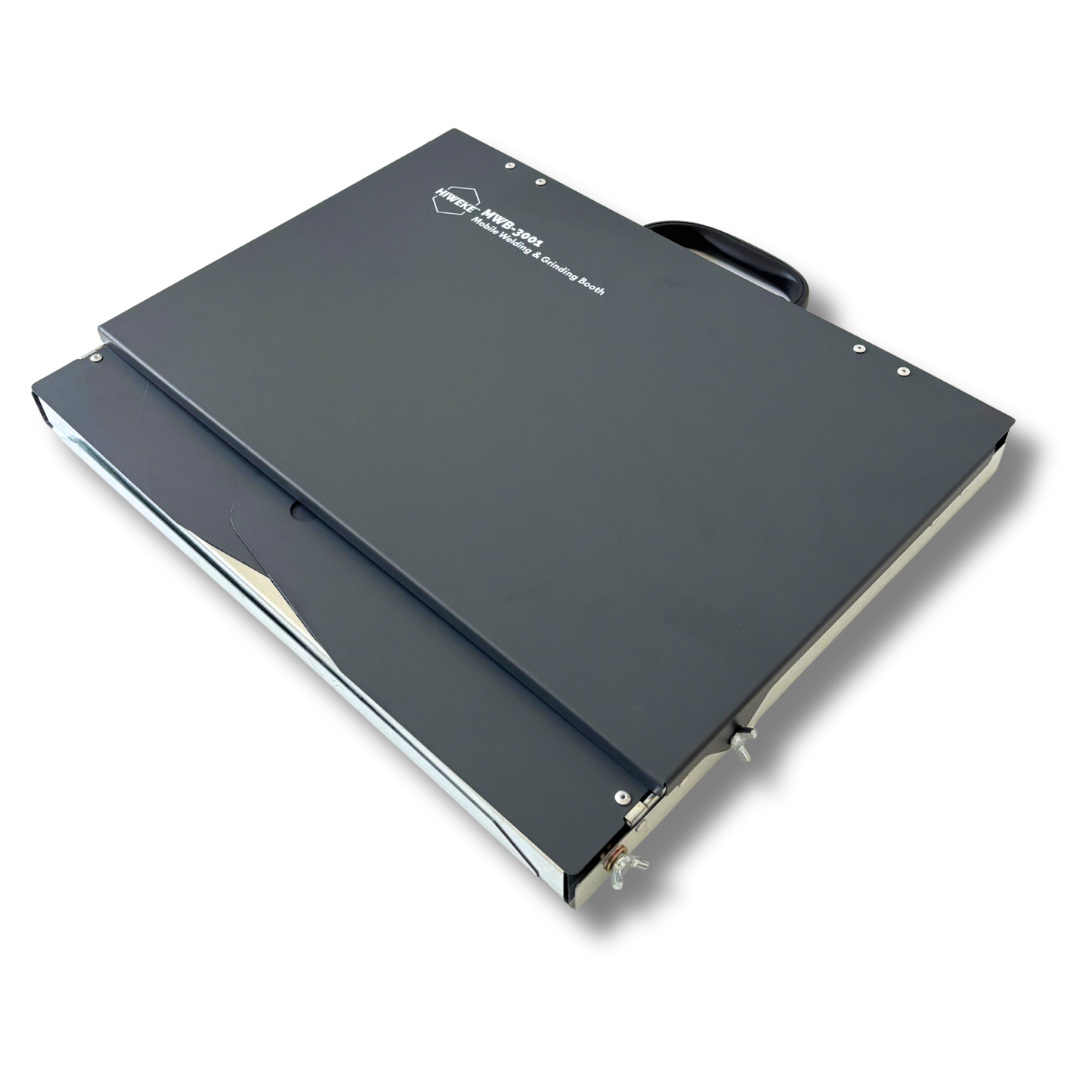

HIWEKE™ Folding Welding & Grinding Station

A defined, rigid welding workspace — without permanent installation.

Engineered for controlled welding and grinding in space-limited environments.

Provides a reinforced steel work surface, integrated grounding, and flat-fold storage for shared shops, classrooms, and mobile setups.

Available April 2026 - For institutional orders and pilot programs, contact us directly.

Pre-Order NowPRODUCT FEATURES

Pre-Order Now-

Reinforced Steel Work Surface

Rigid galvanized steel platform designed for repeatable welding and grinding tasks.

-

Integrated Grounding Provision

Dedicated bonding point engineered for proper electrical grounding of the work surface.

-

Reinforced Fold-Flat Mechanism

Structural hinge system collapses flat for storage while maintaining panel rigidity under load.

Designed for Schools, Training Programs & Organizations

Engineered for instructional and shared workshop environments where safety, repeatability, and storage efficiency are essential.

Typical Use Cases

- Welding schools and vocational programs

- Technical college trade labs

- Maintenance and fabrication training

- Demonstration and mobile teaching environments

Technical Specifications:

Work surface thickness: 2 mm galvanized steel

Folded dimensions: 20 × 16 × 2 in (L × W × H)

Open dimensions: 20 × 16 × 15 in (L × W × H)

Weight: Approx. 19.2 lbs

Distributed static load capacity: 220 lbs

Note:

Designed to support controlled spark containment and defined work zones in training environments. Not a substitute for required PPE or ventilation systems.

Educator & institutional inquiries:

For educator pricing, bulk orders, or institutional inquiries, please contact: info@compliantquality.com

Field Feedback

Pre-Order Now-

“Stable under grinding load. No noticeable panel flex.”

- Anton S., Fixer Upper, Denver, CO -

"Provides defined containment in a shared shop."

- Burt L., DIYer, Austin, TX -

"Would be ideal in a shared training environment where space is limited."

- Kenneth C., Home Inspector, Georgetown, TX

Questions from individual users and training environments

Is this welding station suitable for beginners?

Yes. The defined workspace and quick setup make it suitable for both beginners and experienced welders, especially in training and practice environments.

Q2: What is the benefit of the integrated ground connection?

The integrated grounding point allows the welder to clamp the ground lead directly to the welding station instead of to each workpiece. This simplifies setup, reduces handling of small parts, and supports a more consistent workflow - particularly in training, maintenance, and small-part welding applications.

How does this compare to welding screens or curtains?

Unlike fabric screens, the HIWEKE station uses steel panels and a rigid steel work surface. This improves durability and provides more predictable behavior near sparks and heat.

If the top is open, how does it improve safety?

The station provides localized containment of sparks, spatter, and arc glare. It is intended to complement - not replace - standard PPE and ventilation.

Does the work surface support fixturing like a welding table?

The station is not intended to replace heavy welding tables. It is designed to provide a rigid, compact welding station where permanent tables or booths are impractical.

Why is the HIWEKE station built with sheet stainless steel instead of fire-retardant canvas/curtains?

The HIWEKE welding station uses rigid steel panels rather than fabric curtains to provide a more durable, heat-resistant barrier for welding and grinding activities. Unlike canvas screens, steel panels are better suited for repeated exposure to spatter and grinding debris and support a stable structure for integrated grounding points. This construction is intended for frequent setup and use in training, shop, and maintenance environments.

HIWEKE™ Folding Welding Station

A compact welding workstation designed for controlled welding and grinding in space-limited environments. Provides a rigid work surface, fold-flat storage, and localized containment of sparks and spatter.

Durable

Durable

Fire Resistant

Fire Resistant

This item is a pre-order. Available April 2026.

Industry Insight

Portable welding stations as a practical alternative to fixed booths and welding screens in space-constrained workshop and training environments.

A Defined Welding Workspace — Without Permanent Installation

Reinforced. Grounded. Fold-flat.