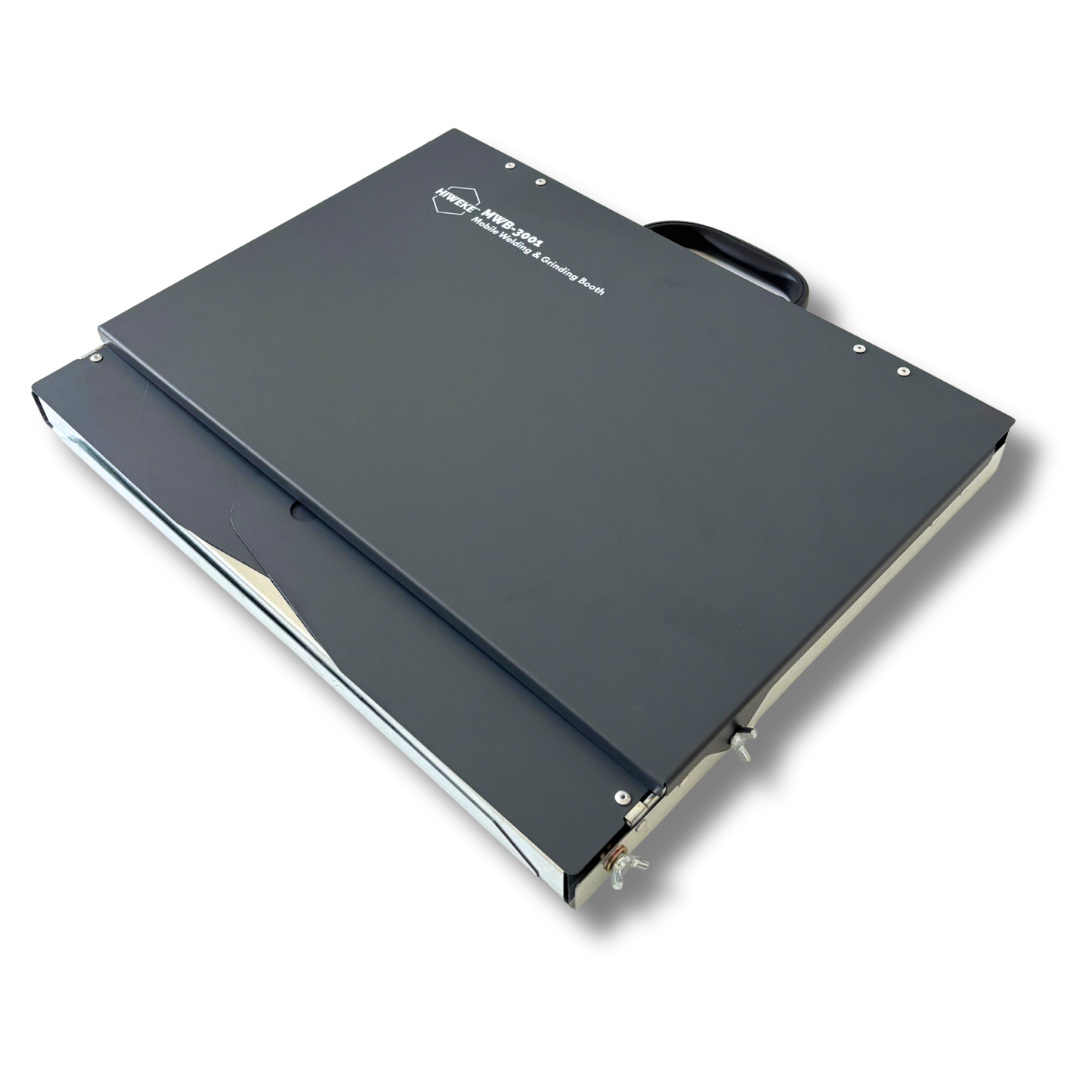

HIWEKE Portable Welding Station

Portable welding and grinding station designed for controlled workspaces in limited environments.

This item is a pre-order. Expected to ship March 2026.

Pre-Order Now — Save 50%-

The Problem: Welding Without a Defined Workspace

Traditional welding setups are often bulky and difficult to adapt to small or temporary spaces. Creating a protected workspace can require makeshift barriers, extended setup time, and compromises in safety and workflow - especially in garages, classrooms, or mobile environments.

-

The Solution: A Compact, Portable Welding Station

The HIWEKE Mobile Welding Station was designed to provide a defined welding area where permanent booths are impractical. Its folding, portable design allows for quick setup and storage while offering localized containment for sparks, spatter, and arc glare.

-

The Result: Controlled Welding Where You Need It

With a dedicated, space-efficient workstation, welders can focus on the task at hand without reconfiguring their surroundings. The HIWEKE station supports safer, more efficient welding in garages, training programs, job sites, and other space-limited or temporary environments.

PRODUCT FEATURES

Pre-Order Now — Save 50%-

Tough Yet Lightweight

Only 12.6 lbs with a galvanized steel base and powder-coated panels built to last.

-

Built-In Ground Points

4 Integrated grounding point ensures secure welding every time.

-

Welding & Grinding in 1

Switch from welding to grinding without changing your setup.

For Schools, Training Programs & Organizations

The HIWEKE Portable Welding Station is designed for instructional and professional environments where space, flexibility, and safety are important.

It supports temporary or overflow welding stations, flexible classroom layouts, and mobile instruction without the need for permanent installation. The station was improved with input from a welding instructor (Round Rock, TX) and is designed for repeated use in training settings.

Use cases include:

- Welding schools and training programs

- Overflow or temporary instructional stations

- Mobile instruction and demonstrations

- Fabrication and maintenance training environments

Safety note:

The HIWEKE station is designed to help contain sparks, spatter, and arc glare. It does not replace required welding PPE or ventilation systems.

Educator & institutional inquiries:

For educator pricing, bulk orders, or institutional inquiries, please contact: info@compliantquality.com

HIWEKE™ Portable Mobile Welding Booth

Portable welding and grinding station designed for controlled workspaces. Sets up in under a minute and helps reduce sparks, spatter, and arc glare in the immediate work area.

Durable

Durable

Fire Resistant

Fire Resistant

This item is a pre-order. Expected to ship March 2026

What Welders Say

Pre-Order Now — Save 50%-

"I take this welding booth everywhere I go. Super space saving and practical ."

- Anton S., Fixer Upper, Denver, CO -

"Finally, I can weld and grind in my garage without covering everything in sparks."

- Burt L., DIYer, Austin, TX -

"It's compact, solid, and makes me efficient on small jobs."

- Kenneth C., Home Inspector, Georgetown, TX

Questions from individual users and training environments

Is this welding booth suitable for beginners?

Yes. The HIWEKE welding station is suitable for both beginners and experienced welders. Its defined workspace and quick setup make it practical for training environments, welding schools, and individual practice, especially where space is limited.

Q2: What is the benefit of the Integrated Ground Connection?

The integrated ground connection allows the welder to attach the ground clamp directly to the station’s frame, eliminating the need to locate a clean ground point on the workpiece or surrounding equipment. This supports consistent grounding and helps streamline setup in both training and practical welding environments.

How durable is the booth compared to standard welding screens?

The HIWEKE welding station is constructed from steel components rather than fabric-based welding screens. The rigid panels are designed to withstand repeated exposure to welding spatter and grinding sparks, and the folding mechanism is intended for frequent setup and storage in training, shop, and mobile environments.

If the top is open, how does it provide safety?

The station creates a defined working area that helps reduce the spread of sparks, spatter, and arc glare within the immediate workspace. The side and rear panels provide localized containment, while the open top allows for natural air movement and flexibility when working on larger parts. The design supports safer work practices when used alongside required PPE and ventilation systems.

Why is the HIWEKE booth built with sheet stainless steel instead of fire-retardant canvas/curtains?

The HIWEKE welding station uses rigid steel panels rather than fabric curtains to provide a more durable, heat-resistant barrier for welding and grinding activities. Unlike canvas screens, steel panels are better suited for repeated exposure to spatter and grinding debris and support a stable structure for integrated grounding points. This construction is intended for frequent setup and use in training, shop, and maintenance environments.

Ready to Upgrade Your Welding Experience?

Durable, portable, and built for performance. Take your projects to the next level!